So many cool winter projects have been shared with photos this year on the various PP Forums. Andy has been outfitting the McCleary Outpost of Suppressed Harbor Seals, Team 6.8, Coley G has twisted up some of the most beautiful flies I’ve ever seen, and Old Duffer’s Toutle, Mountain Goat, & Green River photo essays were simply fantastic. So, I thought to myself, why not?

Mission: Fertilizer Spreader Re-Build

I bought an old broke down fertilizer spreader from the Chehalis John Deere outfit in 1995. The tubular frame was shot but the hopper assembly, wheels and the ring and pinion gears were in real good shape.. I had a wire feed welder so I made a little Auto-Cad sketch & cobbled together a new frame and fit the salvaged hopper assembly, deflector shield, tires, and other salvageable parts to it.

Unfortunately, the original distributor plate was a plastic POS. It was to small and left lots of whatever your were applying sitting on the deck of the spreader and not on the lawn. Hence the need for a new and improved distributor plate.

Here is the Spreader without the tires. The old set-up had a ½” vertical axle. The new shaft assembly is 5’8” diameter.

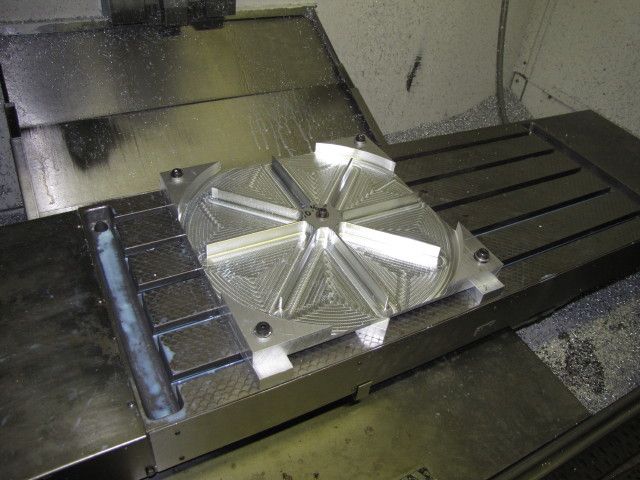

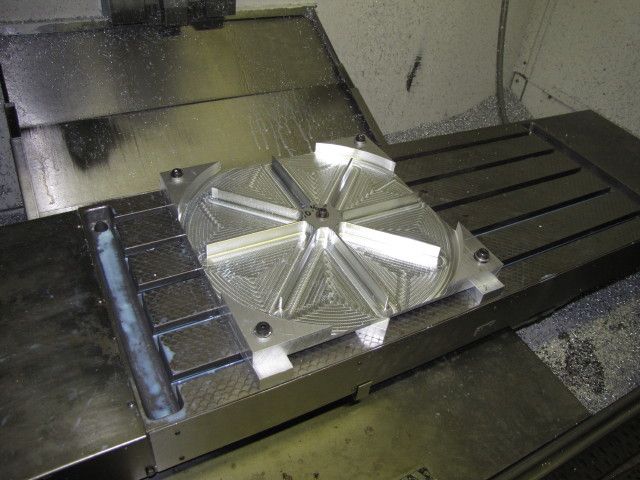

To build the new distributor plate, I bolted some 1” x 2” aluminum bars to my CNC to use as a tooling fixture. Four ½” diameter stripper bolts in the corners precisely locate the 18” x 18” x 1.25”, 41 pound aluminum plate.

First thing I did was rough out the top side with .050 excess on all surfaces. Then I turned the part over and roughed out the eight lightening pockets on the bottom side. Back over it went to have the top side finished.

Now it’s time to finish the lightening pockets on the bottom side, drill and tap the six ¼-20 threaded holes, and use a small end mill to part off the new distributor from the original 41 pound aluminum plate.

Here's what's left of the 41 pound aluminum plate.

Here’s the new 17” diameter, 3.5 pound distributor plate with it’s new Al Ni Br bushing fitted to the new 5’8” diameter vertical shaft.

Here is the new vertical drive shaft assembly. The original pinion gear has a new Al Ni Br bushing and cross bolt. The red spacer locates the pinion gear in position to the ring gear. The new aluminum drive hub with Al Ni Br bushing and cross bolt will drive the new distributor plate. Next there is the Al Ni Br bushing that centers the vertical drive shaft to the center of the hopper assembly. On top of that is the new Al Ni Br cap.

I used a glass bead cabinet to prep all the new parts for powder coating. Here’s the re-built spreader ready for 150 lbs. of granular fertilizer.

It’s spring 2MANY and it’s time to Spread ‘em !

Previous Topic

Previous Topic Index

Index